Cargo port in Johor tests autonomous trucks

MGCC Perspectives

The Malaysian cargo port Tanjung Pelepas focuses on automation and digitalisation. Due to the coronavirus, demand for temporary storage is especially high.

By Werner Kemper

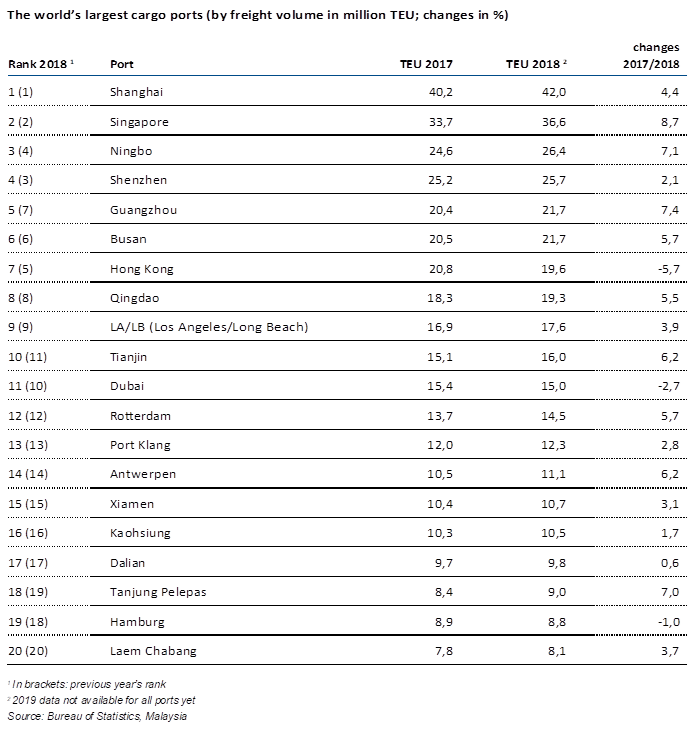

The Port of Tanjung Pelepas (PTP) is located in Malaysia’s southernmost state Johor and borders Singapore directly. PTP is a transit port and moves about 9 million to 9.5 million TEU (twenty- foot equivalent units) per year. The Singapore harbour is directly visible from PTP. Both ports are strategically located in the straits of Malacca, the shortest sea route between the Far East and the Indian Ocean. Marco Neelsen, PTP’s CEO is cautiously optimistic that the prognosis for 2020 of 9.6 million moved TEU can be maintained. “Last year we have achieved 9.1 million TEU and in the first quarter of 2020, everything is pointing towards us reaching our intended target”, opines Neelsen.

“However, at the moment much depends on the further progression of the Corona pandemic”, said Neelsen. In February 2020, PTP as well as Singapore harbour were able to show significant sales increase. Singapore increased by 6 percent, PTP even managed 11 percent. This growth is based on increasing and prolonging temporary storage.

Test phase with autonomous trucks planned

In future, the port PTP will focus more on automation and digitalisation. “In Malaysia wages are quite low, therefore the pressure to automate is not caused by high salary cost”, explains Neelsen. On the contrary, the pressure is caused by low wages and the resulting fluctuation. For a worker, for example a truck driver, 100 to 200 Malaysian Ringgit (RM, ca. 20 to 40 Euro) can be enough to change jobs. It becomes more and more difficult to find sufficiently qualified personnel to carry out comparatively simple jobs.

To escape this dilemma, automation is becoming more and more of a focus in the so-called “horizontal transport”. Autonomous trucks are one of the solutions envisaged. In cooperation with the Dutch company Terberg, which specialises in trucks in terminal business, PTP wants to use autonomous trucks in the port area. Development and testing is planned to take four to five years.

Two digitalisation strategies

PTP pursues two main strategies when it comes to digitalisation, which can be summarised under the key term “asset optimisation”. In a large port, many of the assets are large and expensive. These are needed to function as long as possible, always when required and as cheaply as possible. This means that maintenance must be optimised. It means moving away from reactive maintenance, when something is broken, and also moving away from pre-emptive maintenance, following standardised dealership guidelines, such as every 10,000 kilometres for an oil change or such.

Instead, PTP tries to design the maintenance as proactive as possible by monitoring with sensors. Using years of recorded data and recording values, an optimum date for maintenance can be determined. Marco Neelsen is confident that this pro-active maintenance can help save a lot of costs.

Another asset that can be optimised by digitalisation, is human resources, meaning the work force. Up to now, at years end the employees were given a bonus if the company performed well, and this was done by the sprinkler principle. No matter how good or how bad an individual staff performed, all got the same bonus. Now, for example, all truck drivers have to download an app onto their hand phones which is connected to the central computer in the port. With this app, it is possible to specify which driver moved how many containers in which period. The bonus allocation is therefore done by objective criteria, which leads to a significantly increased motivation.

Optimisation can also be achieved if it is possible to minimise the transport routes on the port area. At the moment, reports Neelsen, each container passes a route of roughly 1,400 meters. For ca. 9 million containers per year, saving even a few meters per container would mean a significant saving in costs.

Free Trade Zone to be extended

Besides the port itself, there is a free trade zone on the area. Here we find branches of not only logistics companies such as DB Schenker, Kühne und Nagel or DHL, but also VW, Adidas and Puma, for example. The Free Trade Zone is subject to continuous expansion. This could be of interest not only to logistics companies but also to companies with a high degree of export orientation and high-volume output. The vicinity to Singapore could be a great advantage. Neelsen explains that for companies who have their company seat in Singapore and are thinking about a production facility or establishing a warehouse without giving up their regional company seat, this could be an ideal location.